纏繞膜機

LLDPE拉伸纏繞膜,是以的LLDPE為基材,別配加質量的增粘劑,經加溫、擠壓、流延,再經激冷輥冷卻而成,具有韌性強、高彈性、防撕裂、高粘性、厚度薄、耐寒、耐熱、耐壓、防塵、防水、有單面粘及雙面粘等優點,在使用時可以節省材料、節省勞動力、節省時間,遍及于造紙、物流、化工、塑料原料、建材、食品、玻璃等方面.

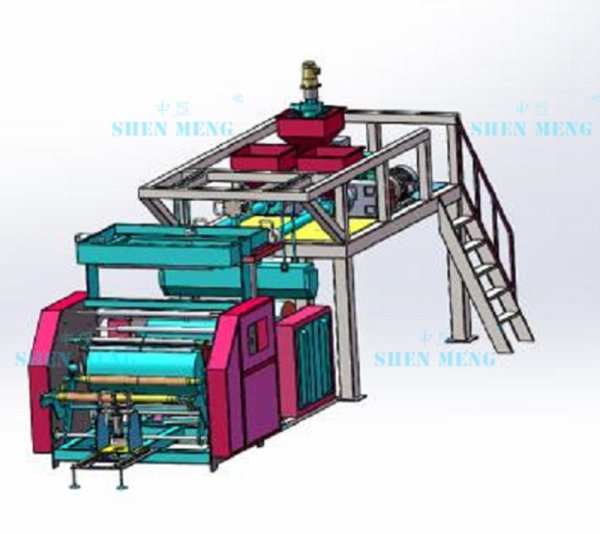

1.纏繞膜機

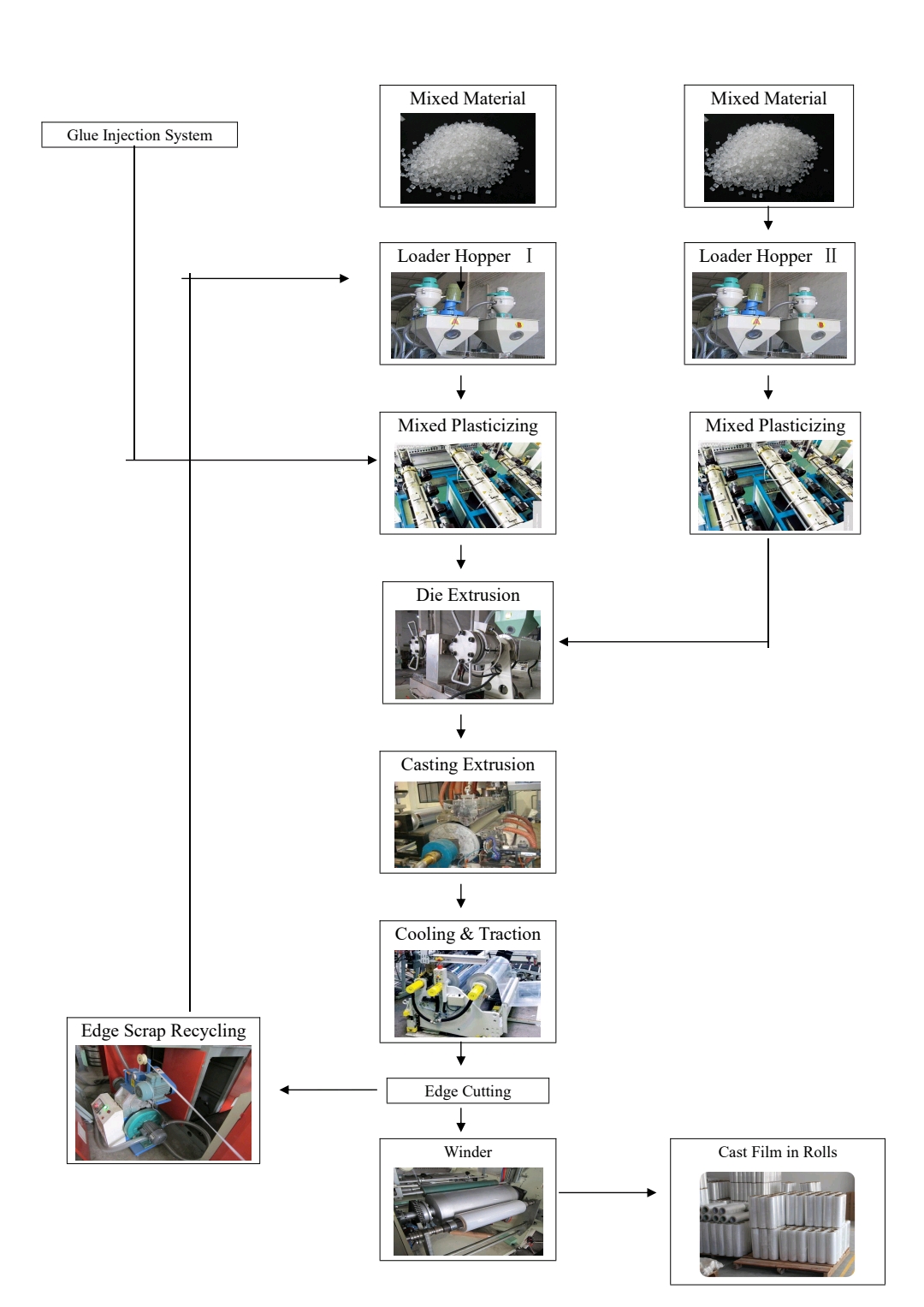

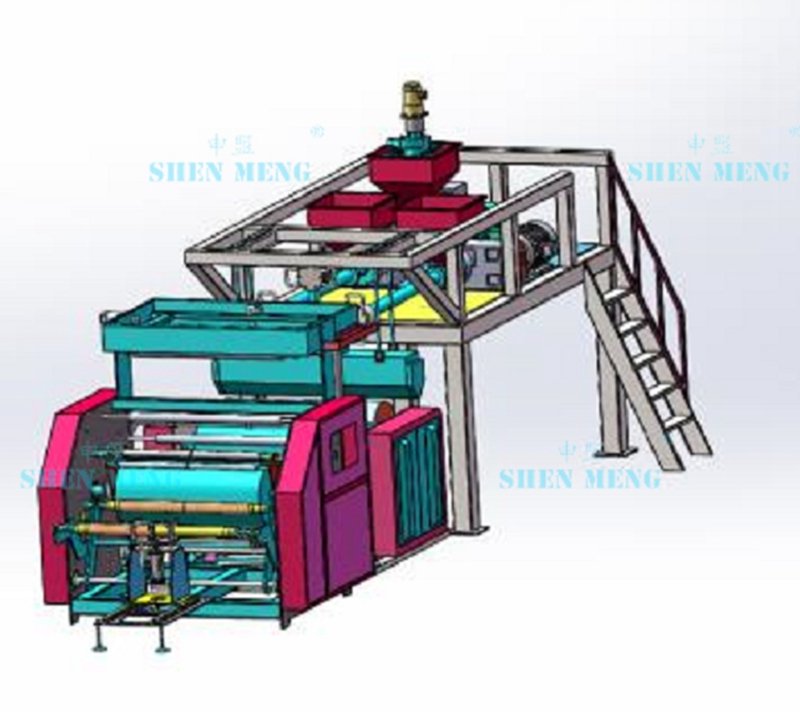

早期LLDPE拉伸膜以吹膜為多,從單層發展到二層、三層;以流延法生產LLDPE拉伸膜為主,其流程見下圖,這是因為流延線生產具有厚薄均勻、透明度高等優點,可適用于高倍率預拉伸的要求。由于單層流延做不到單面粘,應用領域受到局限。單、雙層流延在材料選擇上沒有三層流延的廣,配方成本也高,所以還是以三層共擠的結構較為理想。質量的拉伸膜應具有透明度高,縱向伸長率高,屈服點高,橫向撕裂強度高,穿刺性能好等特點。

2.纏繞膜原理

纏繞膜借助薄膜超強的纏繞力和回縮性,將產品緊湊地、固定地捆扎成一個單元,即使在不利的環境下產品也無任何松散與分離,度且沒有尖銳的邊緣和粘性,以免造成損傷。

3.PE 拉伸纏繞膜特點

PE拉伸膜(又稱纏繞膜)具有較高的拉伸強度、抗撕裂強度,并具有良好的自粘性,因此能使物體裹成一個整體,防止運輸時散落倒塌。該膜具有優良的透明性。包裹物體美觀大方,并能使物體防水、防塵、防損壞。該膜廣泛用于貨物托盤包裝,如電子、建材、化工、金屬制品、汽車配件、電線電纜、日用品、食品、造紙等行業的捆裹包裝。規格:機用膜寬500mm,手工膜寬300mm,350mm,450mm,500mm,厚15um-50um.可在線分切各種規格。粘性分單面粘、雙面粘,產品分手工纏繞膜和機用纏繞膜兩大系列。

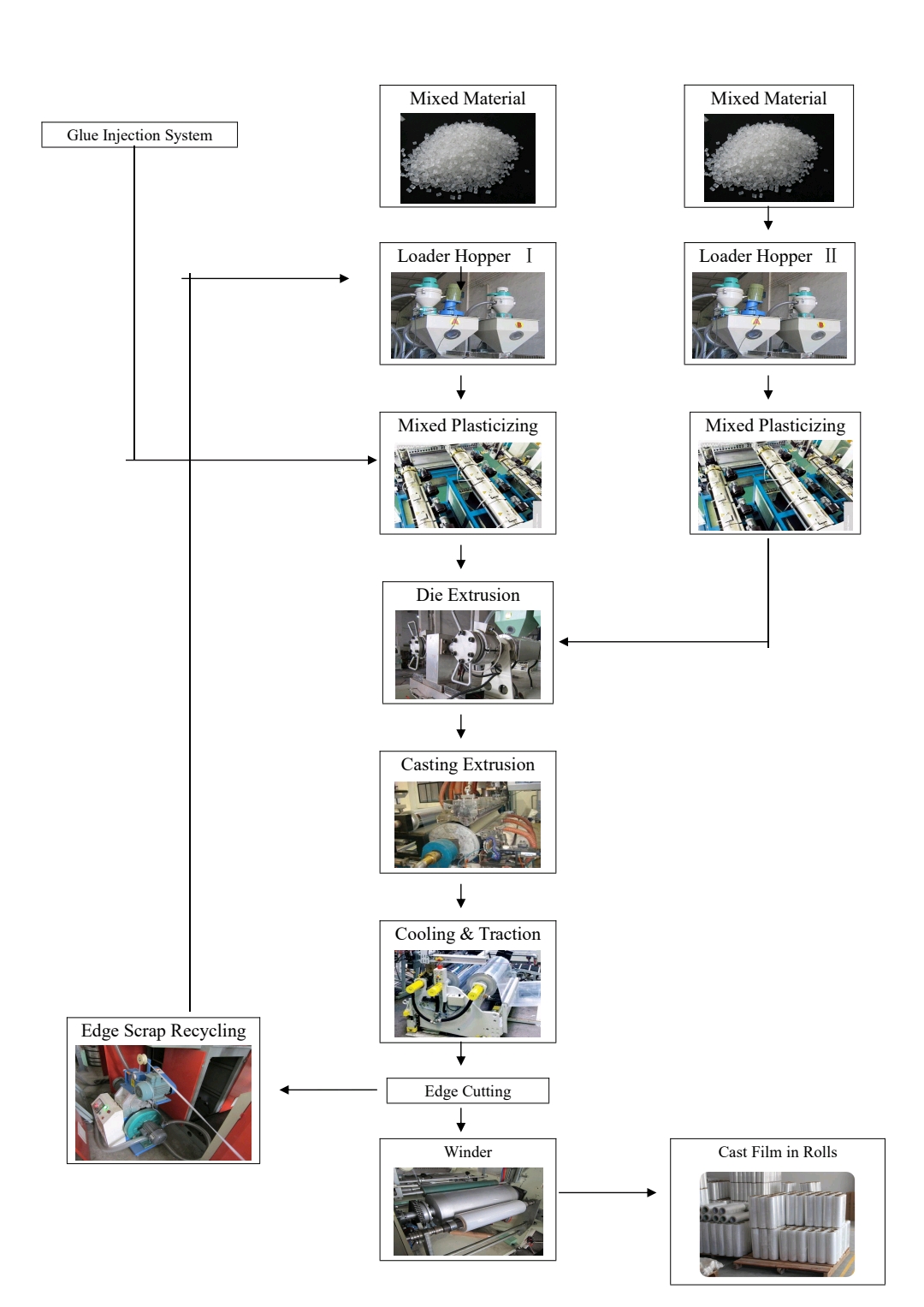

4.PE纏繞膜機生產流程:

5.此生產線優勢 Production line advantage:

1)全新設計:全新升級了螺桿料筒結構、模具內部構造等核心設備,讓整條流水線運行順暢,杜絕了塑化不好,薄膜亮度不夠,收縮效果不佳等現象。

New design: a new upgraded screw barrel structure and the internal structure of the mold core equipment, so that the whole assembly line running smoothly, eliminate the bad plasticized, not enough film bright , poor contraction effect and so on.

2) 量身設計:我公司可根據客戶不同的產品要求,為客戶設計最合理的加工生產線,經濟、實用。

Custom design: Our company can according to customer requirements for different products, for customers to design the most reasonable production line, economical and practical.

3) 核心部件:我公司采用西門子品牌電機,國茂集團減速箱,丹佛斯變頻器控制,電器配置:國際知名品牌法國Schneider;PLC臺灣臺達;臺灣晨邦臥式免維護減速齒輪電機同步帶動;帶動舟山品牌優質螺桿料筒;螺桿采用38CrMoAI合金鋼經氮化,增加硬度及耐腐蝕度,為設備的穩定、高效保駕護航。

Core components: Our company using the Siemens brand motors, Guomao group gearboxes, Electrical Components:Schneider,PLC:Delta,Taiwan;Taiwan Chenbang horizontal maintenance free reduction gear motor synchronous drive;Danfoss frequency converter control, Zhoushan brand quality screw barrel, HRB bearing components, etc., for the stability of the equipment, and efficient escort.

4) 安全方便:所有設備上均貼有警示標貼及定期保養提醒,設備設計上也添加了安全護罩、急停等安全保護措施,產量最大化的同時也給客戶提供一個安全的工作環境。

Safe and convenient: All the devices are affixed with warning labels and regular maintenance reminders, device design also adds security guard, emergency stop and other security measures, while also maximizing production to provide customers with a safe working environment .

5) 培訓安裝:我司有專業的安裝、售后團隊,無論您是在哪個省或者國家,公司都會提供生產線的安裝、調試,并會對客戶的現場操作人員進行生產培訓及日常保養培訓。

Training and Installation: Our company has professional installation and after-sales team, whether you are in the province or the country to which the company will provide production line installation, commissioning, and customers will be produced on-site operator training and routine maintenance training.

7) 質量檢測:我公司通過了ISO9001質量管理體系、機器CE認證,在生產中、出貨前所有設備均會進行質量檢測,并在出貨前接電試機,給客戶提供最佳的質量保障。

Quality Inspection: Our company passed the ISO9001 quality management system, the machine CE certification , in production, all equipment before shipment will conduct quality testing and before shipment electrical connection test machine, to provide best quality assurance.

8)PE纏繞膜機基本參數:

|

纏繞膜機型 |

技術參數 |

|

|

1米機型 |

型號/Model |

SM-70-1250 |

|

螺桿直徑/Screw Diameter |

φ70mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

薄膜原料/Film material |

LLDPE |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW |

|

|

薄膜寬度/Width of effective film |

1000mm(max)/2*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

50-80KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 50kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

About 8000mm*3000mm*2700mm |

|

|

機器重量/Machine weight |

4800KG |

|

|

|

||

|

1米 |

型號/Model |

SM-70-55-1250 |

|

螺桿直徑/Screw Diameter |

φ70mm/φ55 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW /15KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1000mm(max)/2*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

100-120KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 80kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

8500mm*3000mm*2700mm |

|

|

機器重量/Machine weight |

About 6500KG |

|

|

|

||

|

1米 |

型號/Model |

SM-55-70-55-1250 |

|

螺桿直徑/Screw Diameter |

φ55 mm/φ70mm/φ55 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

15KW/22KW /15KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1000mm(max)/2*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

130-160KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 100kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

9000mm*3000mm*3200mm |

|

|

機器重量/Machine weight |

About 8000KG |

|

|

|

||

|

1.5米 |

型號/Model |

SM-70-90-1800 |

|

螺桿直徑/Screw Diameter |

φ70mm/φ90mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW/45KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1500mm(max)/3*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

130-160KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 100kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

10000mm*4000mm*3500mm |

|

|

機器重量/Machine weight |

About 8500KG |

|

|

|

||

|

1.5米 |

型號/Model |

SM-70-90-55-1800 |

|

螺桿直徑/Screw Diameter |

φ70mm/φ90mm /φ55 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW/45KW/15KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1500mm(max)/3*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

150-200KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 120kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

10000mm*4000mm*3500mm |

|

|

機器重量/Machine weight |

About 10000KG |

|

|

|

||

|

2米 |

型號/Model |

SM-80-100-70-2000 |

|

螺桿直徑/Screw Diameter |

φ80mm/φ100mm /φ70 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

37KW/75KW/22KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

2000mm(max)/4*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

260-300KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 200kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

12000mm*4500mm*3500mm |

|

|

機器重量/Machine weight |

About 12000KG |

|

6.設備識圖展示

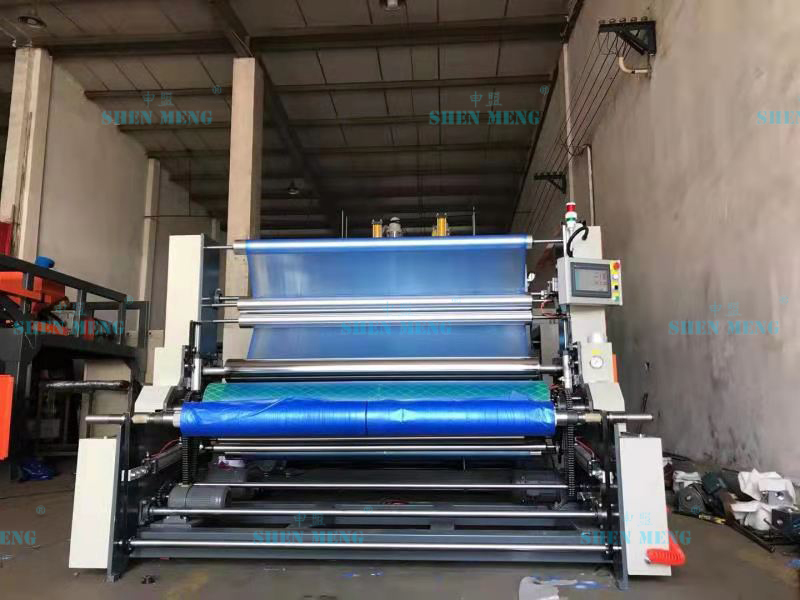

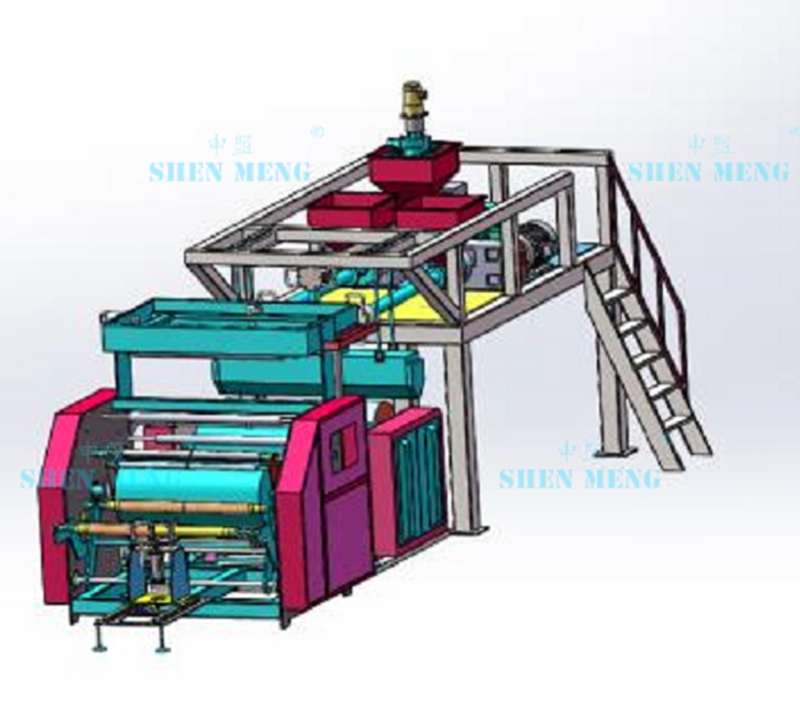

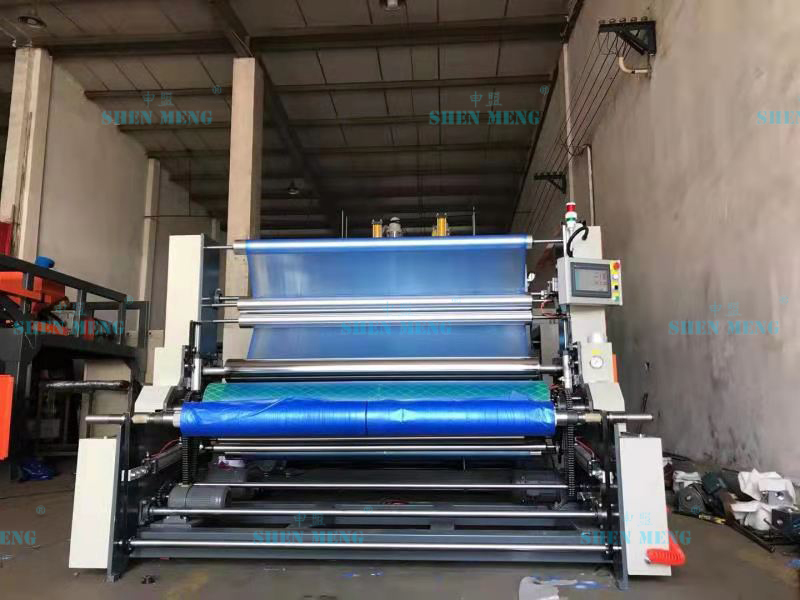

新型1500三層共擠

具有全自動裝卸紙管的功能

1500型

具有自動換卷的功能

CPE TPE一次性手套流延膜機

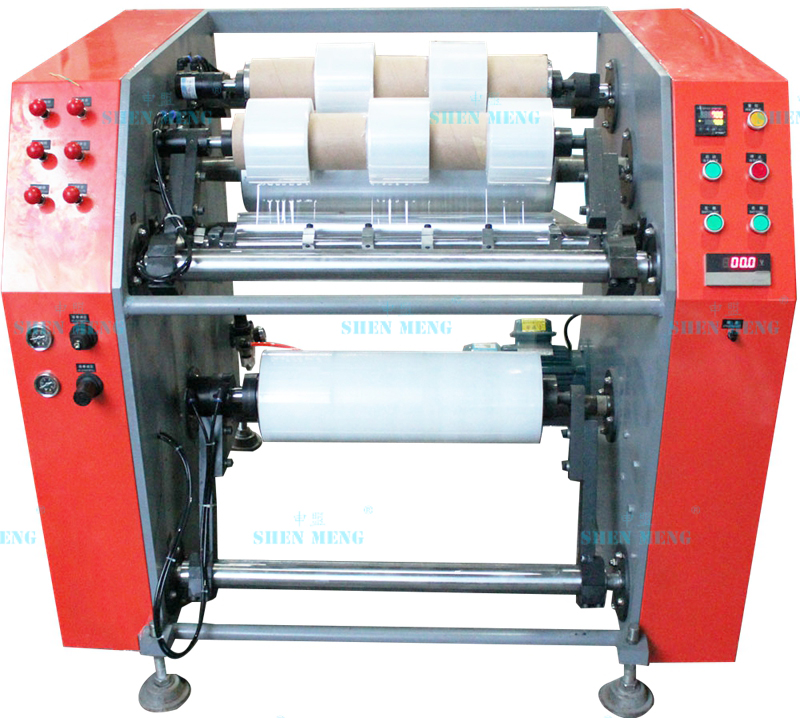

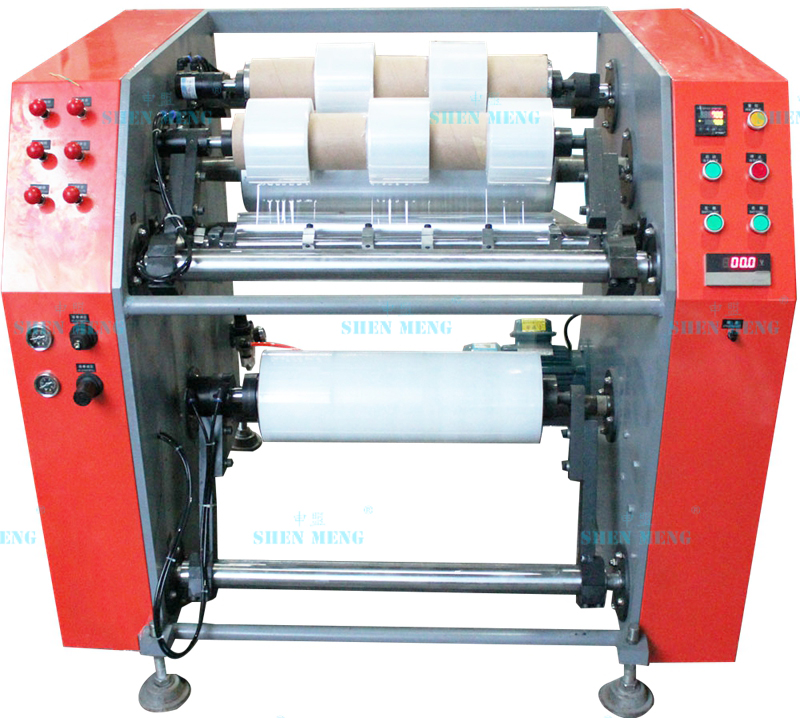

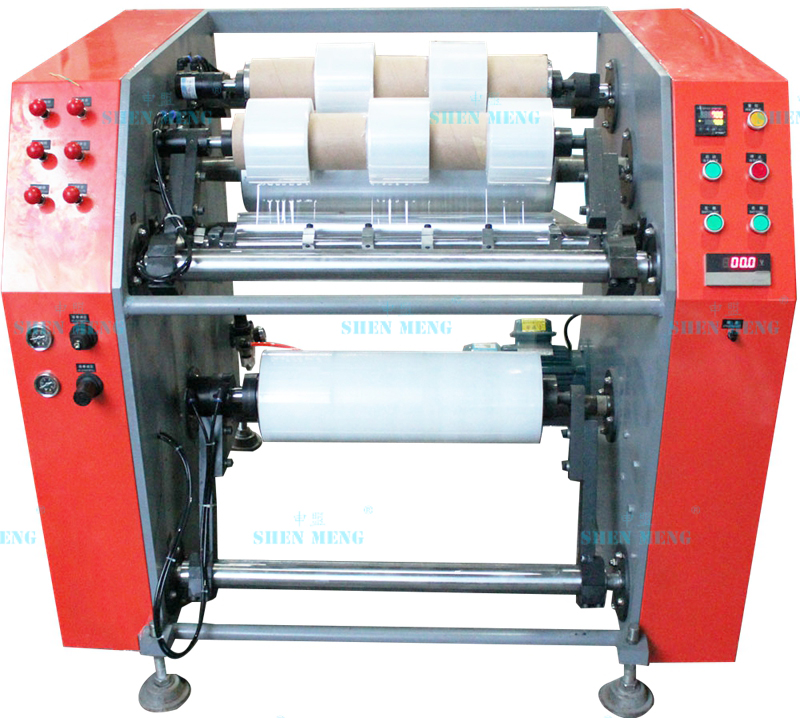

半自動復卷機

自動復卷機

全自動復卷機

1500三層共擠國外客戶工廠

1500三層全自動共擠國外客戶工廠

纏繞膜機

500mm 2l

7.PE熱收縮的應用領域 PE Shrink Film Application A

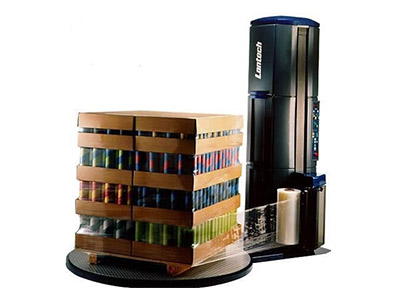

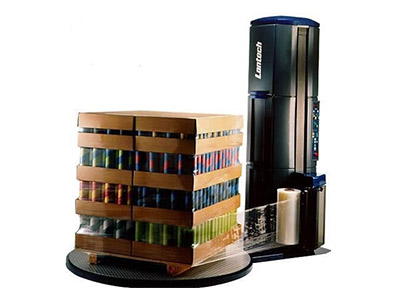

圖示一:纏繞膜機機用包裝展示

圖示二:纏繞膜手動包裝展示

圖示三:纏繞膜機用包裝展示

纏繞膜機

LLDPE拉伸纏繞膜,是以的LLDPE為基材,別配加質量的增粘劑,經加溫、擠壓、流延,再經激冷輥冷卻而成,具有韌性強、高彈性、防撕裂、高粘性、厚度薄、耐寒、耐熱、耐壓、防塵、防水、有單面粘及雙面粘等優點,在使用時可以節省材料、節省勞動力、節省時間,遍及于造紙、物流、化工、塑料原料、建材、食品、玻璃等方面.

1.纏繞膜機

早期LLDPE拉伸膜以吹膜為多,從單層發展到二層、三層;以流延法生產LLDPE拉伸膜為主,其流程見下圖,這是因為流延線生產具有厚薄均勻、透明度高等優點,可適用于高倍率預拉伸的要求。由于單層流延做不到單面粘,應用領域受到局限。單、雙層流延在材料選擇上沒有三層流延的廣,配方成本也高,所以還是以三層共擠的結構較為理想。質量的拉伸膜應具有透明度高,縱向伸長率高,屈服點高,橫向撕裂強度高,穿刺性能好等特點。

2.纏繞膜原理

纏繞膜借助薄膜超強的纏繞力和回縮性,將產品緊湊地、固定地捆扎成一個單元,即使在不利的環境下產品也無任何松散與分離,度且沒有尖銳的邊緣和粘性,以免造成損傷。

3.PE 拉伸纏繞膜特點

PE拉伸膜(又稱纏繞膜)具有較高的拉伸強度、抗撕裂強度,并具有良好的自粘性,因此能使物體裹成一個整體,防止運輸時散落倒塌。該膜具有優良的透明性。包裹物體美觀大方,并能使物體防水、防塵、防損壞。該膜廣泛用于貨物托盤包裝,如電子、建材、化工、金屬制品、汽車配件、電線電纜、日用品、食品、造紙等行業的捆裹包裝。規格:機用膜寬500mm,手工膜寬300mm,350mm,450mm,500mm,厚15um-50um.可在線分切各種規格。粘性分單面粘、雙面粘,產品分手工纏繞膜和機用纏繞膜兩大系列。

4.PE纏繞膜機生產流程:

5.此生產線優勢 Production line advantage:

1)全新設計:全新升級了螺桿料筒結構、模具內部構造等核心設備,讓整條流水線運行順暢,杜絕了塑化不好,薄膜亮度不夠,收縮效果不佳等現象。

New design: a new upgraded screw barrel structure and the internal structure of the mold core equipment, so that the whole assembly line running smoothly, eliminate the bad plasticized, not enough film bright , poor contraction effect and so on.

2) 量身設計:我公司可根據客戶不同的產品要求,為客戶設計最合理的加工生產線,經濟、實用。

Custom design: Our company can according to customer requirements for different products, for customers to design the most reasonable production line, economical and practical.

3) 核心部件:我公司采用西門子品牌電機,國茂集團減速箱,丹佛斯變頻器控制,電器配置:國際知名品牌法國Schneider;PLC臺灣臺達;臺灣晨邦臥式免維護減速齒輪電機同步帶動;帶動舟山品牌優質螺桿料筒;螺桿采用38CrMoAI合金鋼經氮化,增加硬度及耐腐蝕度,為設備的穩定、高效保駕護航。

Core components: Our company using the Siemens brand motors, Guomao group gearboxes, Electrical Components:Schneider,PLC:Delta,Taiwan;Taiwan Chenbang horizontal maintenance free reduction gear motor synchronous drive;Danfoss frequency converter control, Zhoushan brand quality screw barrel, HRB bearing components, etc., for the stability of the equipment, and efficient escort.

4) 安全方便:所有設備上均貼有警示標貼及定期保養提醒,設備設計上也添加了安全護罩、急停等安全保護措施,產量最大化的同時也給客戶提供一個安全的工作環境。

Safe and convenient: All the devices are affixed with warning labels and regular maintenance reminders, device design also adds security guard, emergency stop and other security measures, while also maximizing production to provide customers with a safe working environment .

5) 培訓安裝:我司有專業的安裝、售后團隊,無論您是在哪個省或者國家,公司都會提供生產線的安裝、調試,并會對客戶的現場操作人員進行生產培訓及日常保養培訓。

Training and Installation: Our company has professional installation and after-sales team, whether you are in the province or the country to which the company will provide production line installation, commissioning, and customers will be produced on-site operator training and routine maintenance training.

7) 質量檢測:我公司通過了ISO9001質量管理體系、機器CE認證,在生產中、出貨前所有設備均會進行質量檢測,并在出貨前接電試機,給客戶提供最佳的質量保障。

Quality Inspection: Our company passed the ISO9001 quality management system, the machine CE certification , in production, all equipment before shipment will conduct quality testing and before shipment electrical connection test machine, to provide best quality assurance.

8)PE纏繞膜機基本參數:

|

纏繞膜機型 |

技術參數 |

|

|

1米機型 |

型號/Model |

SM-70-1250 |

|

螺桿直徑/Screw Diameter |

φ70mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

薄膜原料/Film material |

LLDPE |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW |

|

|

薄膜寬度/Width of effective film |

1000mm(max)/2*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

50-80KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 50kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

About 8000mm*3000mm*2700mm |

|

|

機器重量/Machine weight |

4800KG |

|

|

|

||

|

1米 |

型號/Model |

SM-70-55-1250 |

|

螺桿直徑/Screw Diameter |

φ70mm/φ55 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW /15KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1000mm(max)/2*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

100-120KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 80kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

8500mm*3000mm*2700mm |

|

|

機器重量/Machine weight |

About 6500KG |

|

|

|

||

|

1米 |

型號/Model |

SM-55-70-55-1250 |

|

螺桿直徑/Screw Diameter |

φ55 mm/φ70mm/φ55 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

15KW/22KW /15KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1000mm(max)/2*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

130-160KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 100kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

9000mm*3000mm*3200mm |

|

|

機器重量/Machine weight |

About 8000KG |

|

|

|

||

|

1.5米 |

型號/Model |

SM-70-90-1800 |

|

螺桿直徑/Screw Diameter |

φ70mm/φ90mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW/45KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1500mm(max)/3*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

130-160KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 100kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

10000mm*4000mm*3500mm |

|

|

機器重量/Machine weight |

About 8500KG |

|

|

|

||

|

1.5米 |

型號/Model |

SM-70-90-55-1800 |

|

螺桿直徑/Screw Diameter |

φ70mm/φ90mm /φ55 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

22KW/45KW/15KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

1500mm(max)/3*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

150-200KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 120kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

10000mm*4000mm*3500mm |

|

|

機器重量/Machine weight |

About 10000KG |

|

|

|

||

|

2米 |

型號/Model |

SM-80-100-70-2000 |

|

螺桿直徑/Screw Diameter |

φ80mm/φ100mm /φ70 mm |

|

|

長徑比/ Screw L/D |

3 2:1 |

|

|

螺桿材質/Screw material |

38CrMoAL合金鋼 |

|

|

擠出機電機/Extruder motor |

37KW/75KW/22KW |

|

|

驅動方式/Control mode |

Inverter (變頻) |

|

|

薄膜原料/Film material |

LLDPE |

|

|

薄膜有效寬度/Width of effective film |

2000mm(max)/4*500mm |

|

|

厚度/Thickness |

0.013-0.05mm |

|

|

厚度公差/Tolerance of thickness |

≤±5% |

|

|

機械設計線速度/Linear Speed of Machinery |

50-150m/min |

|

|

最大擠出量/Output |

260-300KG/H |

|

|

紙管規格/Paper core size |

Φinner76mm (內徑) |

|

|

總功率/Total Power |

About 200kw (60% of actual use) |

|

|

電壓標準/Electric power supply |

三相380V 50hz 3phase Customized |

|

|

機器尺寸/ Machine size(L*W*H) |

12000mm*4500mm*3500mm |

|

|

機器重量/Machine weight |

About 12000KG |

|

6.設備識圖展示

新型1500三層共擠

具有全自動裝卸紙管的功能

1500型

具有自動換卷的功能

CPE TPE一次性手套流延膜機

半自動復卷機

自動復卷機

全自動復卷機

1500三層共擠國外客戶工廠

1500三層全自動共擠國外客戶工廠

纏繞膜機

500mm 2l

7.PE熱收縮的應用領域 PE Shrink Film Application A

圖示一:纏繞膜機機用包裝展示

圖示二:纏繞膜手動包裝展示

圖示三:纏繞膜機用包裝展示

瀏覽器自帶分享功能也很好用哦~

瀏覽器自帶分享功能也很好用哦~